of sound

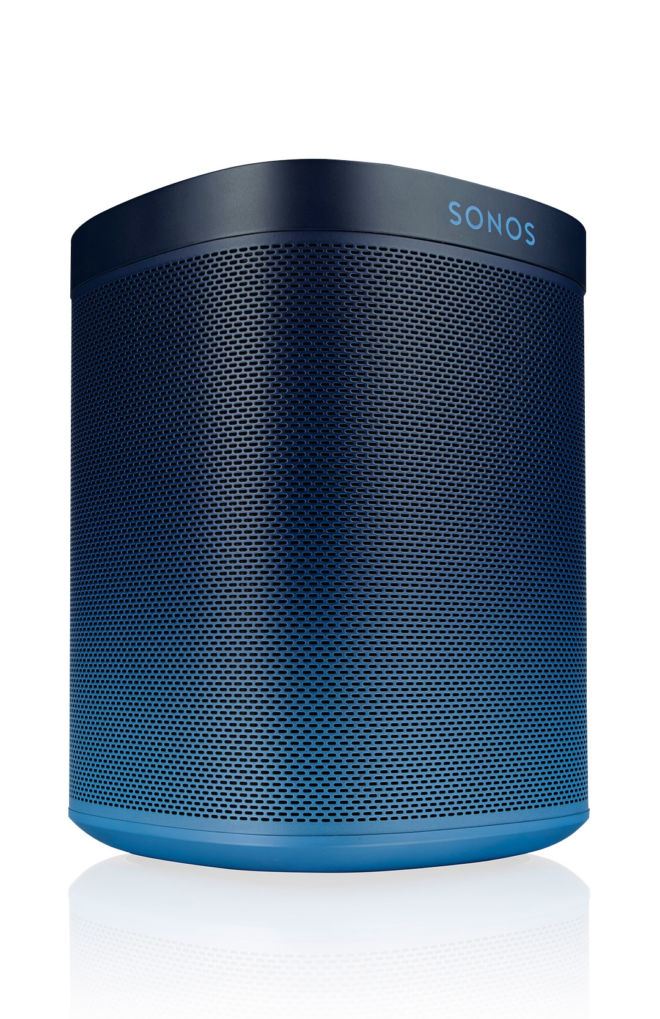

Most admirably, the designers at Sonos are dedicated to creating reliable, beautiful products that will last from 10-20 years, and to achieve this the range of specifications are vast and detailed. Beyond rigorous testing to ensure the product can withstand a variety of harsh conditions and environments, the designers had a very particular problem they asked us to solve. Of the 10,000 speakers being manufactured, the blue gradient of each and every unit was required to fade in the exact same spot. Gradient paint application is typically applied by hand, causing the placement of the color fade to fluctuate by as much as a half inch. So, how do you pinpoint where a color gradient begins? As we set to work finding the solution random batches of 10 speakers would be pulled from the line, lined up against a white background and shot with a camera for comparison – because the human eye is incapable of picking up the difference in gradient placement.

From working closely with Sonos designers to develop custom colors in our lab, inventing a specialized spray gun for the exact application of this project, through to our team’s formulation of completely new hand-painting techniques, as well as creating a process for the strategic use of robots, the speaker’s final finish featured a vertical fade from dark navy to cerulean blue, a much sought after limited edition product which not only sold out in 4 minutes but also crashed global servers in the process. The artistry of a hand-made product coupled with the precision of robotic automation; they are truly a sight to behold.